Achieving a high pellet formation rate (95%+) in biomass pellet production isn’t accidental—it’s engineered. For operators of biomass pellet machines, optimizing feedstock pretreatment is the decisive factor separating mediocre (85%) and premium pellet quality. Here are the five science-backed control points to bridge that gap:

1.pellets Size Uniformity: Target 0.5mm–5mm

Inconsistent pellets size creates weak points in pellets, causing cracks and fines. Research shows:

Corn stalk milled to 0.5mm via planetary ball milling (340 rpm, 3.4g load) boosts enzymatic hydrolysis efficiency, enhancing binding capacity.

Banana straw fragmented to ≤5mm significantly shortens digestion time and improves density—critical for stable pellet formation.

Control Tip: Use a two-stage grinding (coarse + fine) with sieving (e.g., vibrating screens).

2. Moisture Content: Lock at 40%–60%

Moisture lubricates lignin but destabilizes pellets if uncontrolled. Fast pretreatment systems prove:

Adjusting moisture to 40%–60% w/v during extrusion (20 sec, 300°C) maximizes lignin plasticity while minimizing hydrolysis inhibitors.

NaOH pretreatment of banana straw at 90% moisture elevated methane yield by 81.1%—indicating optimized fiber flexibility.

Control Tip: Inject steam or water via sealed ports in biomass pellet machines for real-time adjustment.

3. Thermal/Chemical Pretreatment: Short-Duration & Precision

Lengthy treatments degrade sugars; fast, targeted methods unlock fibers:

Extrusion at 150°–300°C for <20 sec (300–500 psi) minimizes inhibitors like acetic acid (<25 kg/MT) while solubilizing hemicellulose.

PHP (phosphoric acid + H₂O₂) pretreatment generates peracetic acid to break down lignin and pollutants—slashing processing time and boosting fiber accessibility.

Control Tip: Pair dilute acid (2% H₂SO₄) with instant pressure release for rapid lignin depolymerization.

4. Biological Pre-Treatment: Enzymes Over Fungi

While fungi work, enzymes act faster and more predictably:

Laccase (30 IU/g, pH 5, 45°C, 4hr) outperforms white-rot fungi in lignin removal selectivity, creating porous fiber structures ideal for compression.

Xylanase (20 IU/g) removes 25% hemicellulose, shortening fiber length and improving binding.

Control Tip: Enzymes thrive at 40°–50°C—pre-heat feedstock to accelerate reactions.

5. Mechanical Preconditioning: Extrusion Beats Milling

Biomass pellet machines homogenize while activating binders:

Twin-screw extrusion (100–2000 rpm) forms solid “plugs” that separate reaction zones, enabling <15-sec treatment and uniform fiber ejection.

Output increased to 200 dry MT/day with pellets sized at 15–25μm—ideal for pellet machine die filling.

Control Tip: Use biomass pellet machines with pressure-actuated valves to auto-discharge stabilized fiber slurry.

Real-World Impact: From Theory → 95% Pellet Rate

Implementing these controls shifts outcomes:

Crystallinity index ↑ from 37.2% to 46.7% (reed straw after CaO/Na₂CO₃ pretreatment) → harder, stable pellets.

Inhibitors like furfural ↓ to <1kg/MT → no pellet disintegration.

Fiber porosity ↑ (SEM-verified pores) → better machine compaction.

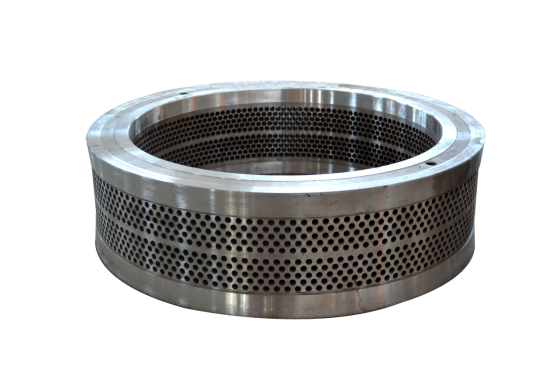

About Shandong Bolida Machinery

A pioneer in pellet engineering, Shandong Bolida integrates these pretreatment principles into its biomass pellet systems. Its biomass pellet machine enable <20-sec thermal-mechanical pretreatment, while adaptive moisture control and pellets-size optimization modules ensure 95%+ pellet formation rates. From lab-tested methods to industrial-scale machines—Bolida turns biomass into gold.

Shandong Bolida Machinery Co., Ltd., established in March 2017, is located in the West side of Dazhan Community in Mingshui Street, Zhangqiu District, Jinan City, Shandong Province with superior geographical location and convenient transportation.

View MoreCopyright © Shandong Bolida Machinery Co., Ltd., All Rights Reserved | Sitemap | Powered by